StepSaver Salt Delivers Smart Solutions for Salt and Brine Management

The Evolution of Winter Maintenance in the North Star State

For decades, salt and brine management for Minnesota municipalities, industrial complexes, and commercial facilities has been a manual, labor-intensive process. In the face of unpredictable “clipper” systems and heavy lake-effect snow, the traditional method of “climb and check” has become a liability. At StepSaver Salt, we recognized that the infrastructure supporting our roads and businesses needed a digital upgrade. We aren’t just a salt supplier; we are a technology-driven partner committed to ensuring that the Twin Cities, St. Cloud, and Greater Minnesota remain safe and operational, no matter how low the temperature drops.

Smarter Service Starts with Smarter Monitoring

At StepSaver Salt, we believe that high-quality service isn’t just about the salt delivery truck showing up—it’s about the intelligence that manages your entire inventory. Historically, tracking both dry salt and liquid brine was a guessing game. Customers had to manually check bins and stick-test tanks, estimate usage based on the weather, and often face the panic of running out during a blizzard.

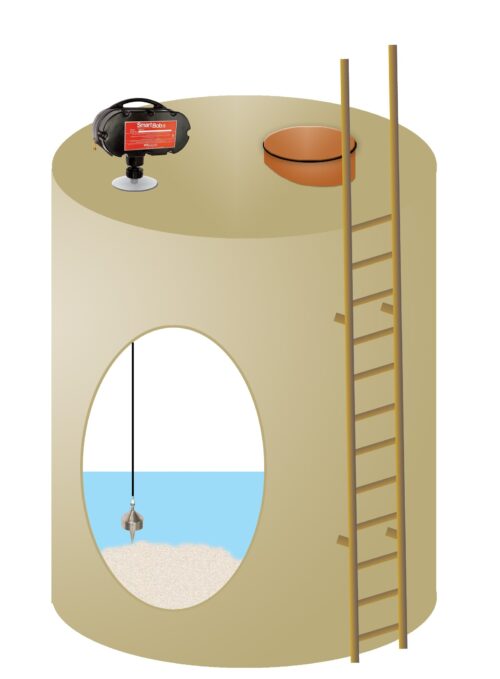

We are changing that dynamic by moving from reactive management to proactive prevention. By investing in advanced remote monitoring technology—specifically BinMaster SmartBob level sensors and BinCloud® inventory software—we provide our customers with a “window” into their storage assets that never closes. This shift toward “Smarter Service” provides three core advantages:

- Data-Driven Reliability: We replace “estimated guesses” with hard data. Whether you are storing bulk road salt or managing liquid brine for pre-wetting and anti-icing, our system ensures you are never caught off guard.

- Operational Safety: Minnesota winters are notoriously unforgiving. Climbing a metal ladder on a salt silo or leaning over a brine tank in sub-zero temperatures is a significant safety risk. By eliminating the need for manual checks, we prioritize employee wellness.

- Total Inventory Visibility: Many facilities utilize a combination of dry salt and liquid brine. Our technology monitors both, giving you a unified dashboard for your entire winter maintenance arsenal.

Continuous Visibility for MN Municipalities & Businesses

With StepSaver’s smart monitoring service, you can check your inventory anytime, from anywhere. Each SmartBob sensor measures the actual level of salt inside a bin or brine inside a tank and sends that data directly to the BinCloud platform.

- Real-time bin and tank levels: Accessible online or via mobile devices for 24/7 visibility. Whether you are at the office or monitoring a storm from home, you have the data you need.

- Automatic alerts: Notifications are sent the moment your salt or brine levels hit your custom refill thresholds.

- Usage history and reporting: Data-driven insights help you track how much brine was used per lane-mile or how quickly your salt pile is diminishing during a sustained weather event.

- Optimized Salt Delivery Scheduling: By monitoring your usage rates, we can ensure your salt deliveries are timed perfectly, preventing the “emergency call” cycle.

The True Cost of Manual Inventory Management

Many organizations underestimate the hidden costs of traditional inventory management. When a facility runs out of salt or discovers an empty brine tank in the middle of a Minnesota winter, the consequences go far beyond a simple inconvenience. There is the emergency premium, the potential for facility downtime, and the liability risk of untreated surfaces.

Furthermore, manual monitoring of liquids like brine is prone to error. Gauges can freeze or fail, and manual readings are often inconsistent. By automating brine management alongside salt monitoring, StepSaver Salt removes the margin for error. We provide a level of precision that protects your bottom line and ensures that when the plow trucks are ready to roll, the materials are ready to be loaded.

Dependable Technology for Harsh Northern Winters

StepSaver relies on BinMaster’s proven SmartBob cable-based level sensors. These are not delicate electronics; they are designed for the “heavy metal” world of industrial storage and the corrosive nature of salt environments.

- Extreme Weather Resistance: These sensors are built to withstand the extreme temperature swings of the Upper Midwest, from 90°F in the summer to -30°F in the dead of winter.

- Accuracy in Solids and Liquids: While salt silos can be dusty, brine tanks require sensors that aren’t affected by fumes or surface foam. The SmartBob uses a physical weighted cable to find the exact level of salt or liquid every time.

- Cloud Integration: Combined with BinCloud, a secure cloud-based software system, this technology gives StepSaver a comprehensive view of every customer site. This allows our team to anticipate salt needs and helps you plan your brine production more efficiently.

Delivering More Than Salt to the North Star State

With this smart monitoring solution, StepSaver is transforming the way Minnesota operations manage their winter assets. By connecting reliable sensor data with an intuitive online dashboard, we help municipalities, utilities, and commercial operations save time, reduce manual labor, and avoid costly shortages.

Our investment in technology reflects StepSaver’s commitment to exceptional service, a reliable regional supply, and long-term partnerships. We don’t just sell salt; we provide the tools you need for comprehensive salt and brine management. From the industrial corridors of the Twin Cities to the municipal sheds of Greater Minnesota, StepSaver is the gold standard for winter logistics.

Frequently Asked Questions

How does the remote monitoring system work for both salt and brine?

The system uses a SmartBob sensor mounted at the top of your storage vessel. For salt, it drops a weighted bob to the surface. For brine tanks, it uses a specific weight designed to detect the liquid level. This data is transmitted to the BinCloud® platform for easy viewing.

Do I need to have Wi-Fi at my salt shed or brine tank?

No. Our sensors can operate on a dedicated cellular connection, which is ideal for remote municipal salt sheds or outdoor brine storage areas where internet access is unavailable.

We make our own brine; how does this help us if StepSaver only delivers the salt?

Even if you produce your own brine, you need to know exactly how much you have on hand to stay ahead of a storm. Our monitoring technology allows you to track your brine inventory alongside your salt supply in one place, ensuring your production team knows exactly when to start the next batch.

How does this improve safety for my employees?

In Minnesota, ice buildup on silo ladders and brine tank catwalks makes manual checking a high-risk activity. Our system keeps your team safely on the ground.

Can I use this data for my annual budget planning?

Absolutely. The BinCloud® software provides detailed usage history for both salt and brine. This is an invaluable tool for Minnesota public works departments to justify seasonal spending and track “salt vs. brine” effectiveness over time.

What happens if there is a sudden spike in usage due to a major storm?

Because the system provides real-time alerts, both you and StepSaver are notified immediately when your salt levels hit a specific threshold. This allows us to prioritize your salt delivery so your brine-making and salting operations never stop.

Ready to Simplify Your Minnesota Salt & Brine Management?

Join the growing number of MN customers who trust StepSaver Salt to keep their operations running smoothly. Don’t let your inventory levels be a mystery this season. Visit StepSaverSalt.com to learn more about our remote monitoring solutions—or contact our Minnesota team today to set up your smart salt and brine service.